Anti-Explosion Flashlight

A high-lumens and ATEX-rated right angle flashlight to be used in Zone 0 and mining locations.

Read MoreHeat sink, the purpose of heat sink is to reduce heat resistance and to increase heat flow to keep LED Working temperature within an appropriate range.

Natural convection is through the heat sink (such as fins, lamp shells, wire system boards... etc.) and air to conduct direct contact. The air around heat sink becomes hot air by absorbing heat; when hot air rises & cold air goes down, the air convection will naturally achieve cooling effect. With the launch of high-power lighting products, heat sink is introduced to help increasing cooling surface area to reaching natural convection purpose.

Currently LED lifetime and brightness is influenced seriously by heat dissipation for which the main light is concentrated in a small light-emitting chip. The lifetime of LED would be exceed to 300,000 hours if temperature could be controlled under 30°C ( It would be around 34 years lighting). But, this theory is only limited in special laboratory. How to solve the heat dissipation of LED is still a main topic in current technology.

In addition to use a good conductive material, it needs to take into account the surface area, aerodynamics, and external factors. Heat is am energy which needs to consider its heat conductive method (Heat transfer process from high temperature to low temperature). There are 3 methods to achieve conduction heat: Conduction, Convection & Radiation, three methods.

Day Sun uses the following heat conductive design: by applying MCPCB + heat sink structure and air vent to increase air convection.

This kind of design has an excellent cooling effect and can effectively control / solve LED light failure problems arising due to high temperature.

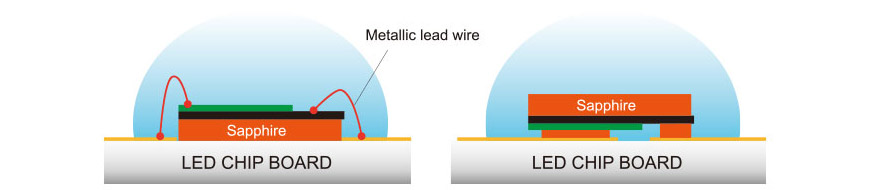

In Wafer Packaging, we use wire bonding, Eutectic bonding or Flip Chip Bonding to assemble the chips and heat sink. Wire bounding is made by linking metal conductive wire, Led Chip and PCB board. The heat produced by the chip could only be dissipated by conductive wire. The effect is limited and influenced by wire material and shape. In contrast, the joint method by using eutectic bonding or FCB is significantly reducing wire length and increase the wire cross-sectional area which enhance heat dissipation conductivity.

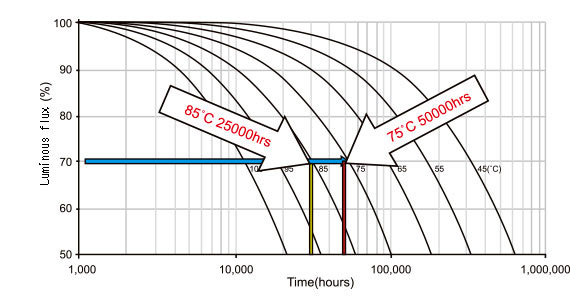

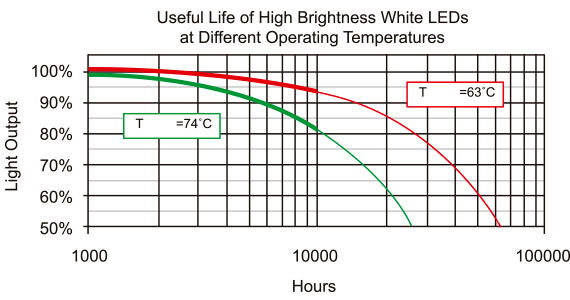

LED luminous efficiency, lifetime and temperature are closely related and shown as an inverse relationship. Below is published by the American CREE LED life report, when temperature dropped 10°C, the LED life will be extended two times and the flux is increased byf 3% to 8%.

LED luminous efficiency, lifetime and temperature are closely related and shown as an inverse relationship. Below is published by the American CREE LED life report, when temperature dropped 10°C, the LED life will be extended two times and the flux is increased byf 3% to 8%.

A high-lumens and ATEX-rated right angle flashlight to be used in Zone 0 and mining locations.

Read More

Best Choice PPE offer a range of protective eyewear for hazardous working conditions. Welcome to our website...

Read More

The sport collection has catching design and comfortable wearing experience for daily outdoor active.

Read More